As the travel and hospitality industry evolves, Agentic AI is quickly becoming a game changer. This technology enhances customer interactions, optimizes operations, and drives profitability. From Contact Centers with Agentic AI improving customer support to Agentic AI in Robotics streamlining automation in hospitality, this technology is reshaping the sector. In this blog, we will explore how Agentic AI plays a pivotal role, from its challenges and impacts to top use cases and next steps for the industry.

The Transformative Role of Agentic AI in Travel and Hospitality

Agentic AI refers to intelligent systems that autonomously manage tasks, make decisions, and improve user experiences. Unlike other AI types, Agentic AI automates complex tasks, makes real-time decisions, and continuously learns, making it ideal for streamlining processes and personalizing guest services. A key application is Agentic Process Automation (APA), which automates booking systems and reduces processing costs, allowing staff to focus on high-value activities that drive growth.

As the hospitality industry embraces the digital era, AI-powered automation is transforming service delivery, with smarter, data-driven operational decisions and more intuitive customer experiences.

Major Challenges in the Travel and Hospitality Industry

The hospitality sector faces several challenges that hinder growth and operational efficiency:

Fig 1: Travel and Hospitality Industry Challenges

Fig 1: Travel and Hospitality Industry Challenges-

Operational Complexity: Hotels have to juggle multiple departments, from housekeeping to front desk operations, often without real-time insights into performance or customer satisfaction. Agentic AI in Robotics helps streamline back-end tasks, from automated check-ins to housekeeping management.

-

Labor Shortages and High Turnover: The demand for skilled labor in hospitality is high, yet finding qualified staff remains challenging. The industry often experiences high employee turnover, resulting in increased recruitment and training costs, as well as a loss in service quality. AI-driven Intelligent Automation with Agentic AI reduces dependency on manual labor while maintaining service excellence.

-

Operational Inefficiencies: Manual processes, lack of data-driven decisions, and poor resource allocation lead to inefficiencies in inventory management, staffing, and guest services. Agentic AI in Data Democratization enables businesses to leverage integrated insights for better resource allocation.

-

Rising Guest Expectations: As competition intensifies, there is growing pressure to meet the ever-increasing expectations of modern travelers, requiring more personalized and responsive services.

-

Increased Competition: With the rise of online travel agencies and new entrants, traditional hospitality businesses need to continuously innovate to retain their market position.

-

Fragmented Data Systems: Many companies struggle with integrating diverse data sources, which limits the potential of AI-driven insights.

-

Security and Privacy Concerns: As AI systems collect and analyze customer data, ensuring robust security and privacy becomes critical.

Addressing these challenges is key to harnessing the full potential of agentic AI.

How Agentic AI is Impacting the Hospitality Industry

Agentic AI is already having a profound impact on how the hospitality industry operates:

Enhanced Customer Experiences

AI uses guest data to automatically adapt services based on preferences and behaviors. For example, AI can track guest preferences from past stays and ensure that rooms are pre-set to the exact temperature, lighting, and other preferences before guests even check in. This kind of personalization not only enhances guest satisfaction but also fosters long-term loyalty.

Operational Cost Reductions

AI-powered systems can handle tasks that traditionally required human intervention. These systems adjust resource allocation, such as staffing and room availability, based on real-time data, ensuring high service levels even during peak demand times while optimizing operational costs.

Revenue Optimization

AI systems continuously monitor market conditions, competitor pricing, and booking trends to automatically adjust room rates. This dynamic pricing ensures that hotels remain competitive and maximize revenue without sacrificing occupancy. By analyzing demand forecasts, Agentic AI can predict the optimal price for every room at any given time.

Competitive Edge

Early adopters of agentic AI are setting new benchmarks in service quality and operational efficiency, positioning themselves ahead of competitors. The overall effect is a more agile, responsive, and customer-centric industry.

Predictive Maintenance

Agentic AI can predict when hotel infrastructure (e.g., HVAC systems, elevators, plumbing) will require maintenance by analyzing patterns in operational data. By identifying issues before they occur, hotels can avoid costly downtime and ensure that facilities are always running smoothly.

Smart Staffing and Workforce Management

By analyzing factors like guest volume, weather conditions, and historical data, AI can determine the optimal number of staff members required at different times of day, improving both guest satisfaction and cost management.

Enhanced Customer Support

AI systems empower chatbots and virtual assistants to handle guest inquiries and requests autonomously, offering quick and accurate responses. Whether it's booking a reservation, ordering room service, or answering frequently asked questions, AI can provide guests with instant support, improving both operational efficiency and guest experience

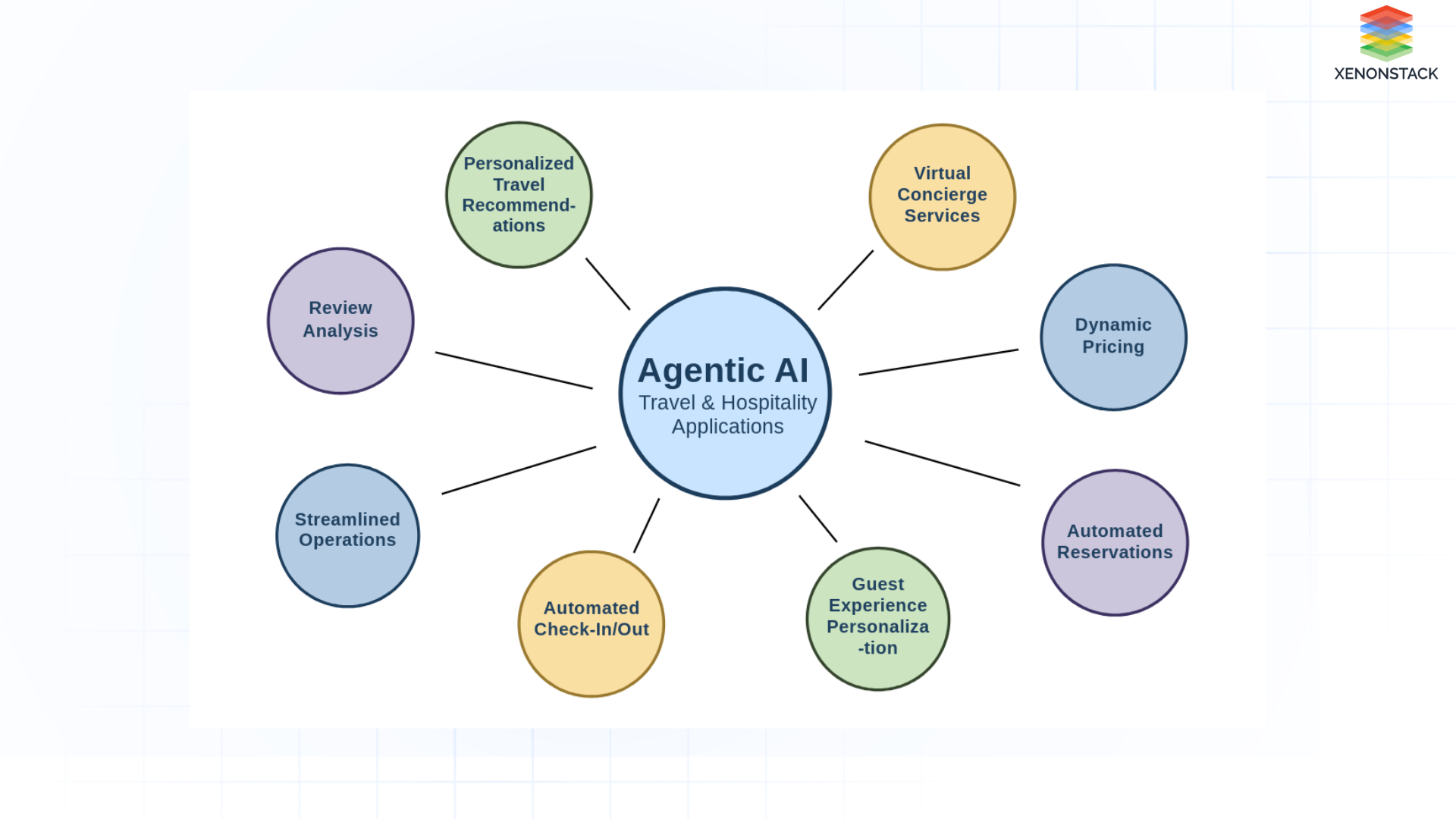

Top Agentic AI Use Cases in Travel and Hospitality

Fig 2: Agentic AI Travel and Hospitality Use Cases

Fig 2: Agentic AI Travel and Hospitality Use CasesPersonalized Travel Recommendations

Agentic AI systems make personalized travel a reality by analyzing vast amounts of customer data—including past travel history, preferences, and even social media interactions—to generate customized recommendations.

-

Data Analysis: These AI systems process historical booking patterns, reviews, and feedback to understand what each traveler truly enjoys.

-

Tailored Suggestions: By using machine learning algorithms, the AI creates a profile for every customer, recommending destinations, accommodations, and experiences that align with their unique tastes.

-

Enhanced Conversion Rates: Personalization increases customer satisfaction and trust. When travelers see options that closely match their interests, they are more likely to make bookings, leading to improved conversion rates and customer loyalty.

Additionally, Agentic AI suggests personalized activities, restaurants, and local attractions based on guest profiles, further enhancing their experience.

Virtual Concierge Services

Virtual concierge services, powered by agentic AI, offer round-the-clock assistance, ensuring that guests receive immediate and relevant support, no matter when they travel.

-

24/7 Availability: Virtual concierges provide immediate answers to common queries, booking reservations, or offering local insights.

-

Multilingual Support: These systems can communicate in multiple languages, ensuring a seamless experience for international travelers.

-

Integration with Mobile Apps: Whether through a dedicated app or integrated within the hotel's management system, virtual concierges ensure that help is always at the fingertips of guests.

Powered by Natural Language Processing (NLP), APA chatbots handle inquiries 24/7, including room availability, check-in/out times, and amenities information, automating modifications and cancellations to reduce inefficiencies.

Automating Invoice Processing

Agentic AI streamlines invoice handling for hospitality providers by automating data extraction, validation, and approval workflows, reducing human errors and processing time. Additionally, it ensures real-time tracking of invoices and accelerates financial reconciliation.

Fig 3: Invoice Processing Flow

Fig 3: Invoice Processing Flow

How It Works:

-

Step 1: Invoice Collection – The system retrieves invoices received via email from vendors and organizes them for processing.

-

Step 2: Attachment Processing – All invoice attachments are saved in a local folder, ensuring they are readily available for extraction.

-

Step 3: Data Extraction – AI intelligently extracts key details such as vendor name, invoice amount, due date, and tax information with high accuracy.

-

Step 4: System Entry – Extracted data is automatically updated in the financial portal, ensuring real-time financial visibility.

-

Step 5: Approval Workflow – The system routes invoices through a structured approval process before initiating payment, reducing delays.

-

Step 6: Record Keeping – Processed invoices are securely stored for compliance and can be shared via email or accessed in audit trails when needed.

This automation eliminates manual errors, speeds up invoice approvals, and ensures accurate financial records, significantly improving operational efficiency.

Dynamic Pricing and Revenue Management

Through predictive analytics, AI systems optimize pricing strategies in real time, adapting to changing market conditions to maximize revenue.

-

Real-Time Analytics: AI monitors market demand, competitor pricing, seasonal trends, and occupancy rates to determine the optimal price for each booking.

-

Flexible Pricing Models: Prices are adjusted dynamically based on real-time factors, ensuring competitive rates during high-demand periods and attractive rates during off-peak times.

-

Predictive Algorithms: By forecasting future trends, AI enables proactive revenue management, preparing businesses for market shifts before they occur.

Enhancing ERP Systems with AI-Driven Automation

Agentic AI optimizes ERP operations by automating data processing, VAT calculations, and financial reporting, ensuring seamless workflows with minimal human intervention.

Fig 4: ERP System Flow

Fig 4: ERP System Flow

How It Works:

-

Step 1: Scheduled Execution – The bot executes automated tasks at predefined intervals daily, ensuring continuous workflow.

-

Step 2: ERP System Login – Using secured credentials, the bot logs into the ERP system without manual input.

-

Step 3: Data Retrieval – The system identifies and extracts essential financial reports and transactional data from the ERP.

-

Step 4: VAT Calculation – AI processes and calculates VAT accurately, eliminating manual miscalculations.

-

Step 5: Financial Processing – The extracted and processed data is formatted and shared with the finance team for reconciliation.

-

Step 6: Monthly Report Storage – All processed reports and financial records are archived in structured folders, ensuring easy access for audits.

By automating ERP tasks, businesses enhance data accuracy, eliminate redundancy, and ensure smooth collaboration between logistics and finance teams, reducing workload and boosting efficiency.

Automating Hotel and Travel Reservations

Traditionally, hotel bookings require manual confirmation by hotel staff. Travel agents send reservation requests via email, which the hotel manager checks for room availability before entering the details into the system.

-

AI-powered bots scan emails from travel agents and extract booking requests.

-

The system checks real-time room availability and updates the hotel reservation software.

-

Confirmation emails and invoices are automatically sent to travel agents and customers.

APA streamlines the booking process, reducing errors and delays. The automated system ensures fast, accurate booking completion, allowing staff to focus on higher-priority tasks.

Optimizing Inventory Management with AI

Agentic AI ensures real-time inventory tracking, preventing stock shortages, minimizing overstocking, and streamlining procurement for efficient inventory management.

.png?width=922&height=525&name=Flow%20of%20Inventory%20Management%20System%20_%20RPA%20Use%20Cases%20in%20Manufacturing%20(1).png) Fig 5: Inventory Management System Flow

Fig 5: Inventory Management System Flow

How It Works:

-

Step 1: Email Monitoring – The system continuously scans incoming emails for stock replenishment requests, ensuring no orders are missed.

-

Step 2: Data Extraction – Item details, quantities, and required stock levels are captured and logged into the system.

-

Step 3: System Update – Inventory levels are updated automatically, ensuring accurate stock records.

-

Step 4: Stock Level Analysis – The agent evaluates stock availability against predefined thresholds, preventing shortages.

-

Step 5: Low Stock Alert – If an item falls below the minimum required quantity, an automatic alert email is generated for restocking.

-

Step 6: Reporting – A daily inventory report is compiled and sent to the relevant team, allowing proactive decision-making.

Automating Check-In and Check-Out Processes

APA allows hotels to implement self-service kiosks and mobile check-ins, enhancing the guest experience and reducing dependency on front desk staff:

-

Guests receive automated check-in confirmations via email or mobile app.

-

The system assigns digital room keys that can be accessed through smartphones.

-

Upon departure, APA automates the billing and payment, generating invoices and sending them to guests electronically.

This automation not only speeds up the check-in/check-out process but also reduces human errors and operational costs, allowing the staff to focus on more personalized guest services. Additionally, it enhances guest satisfaction by providing a seamless and contactless experience.

Automating Hotel Bookings with AI

Agentic AI streamlines hotel reservation management by processing booking emails, updating hotel systems, and automating confirmations to enhance customer satisfaction.

Fig 6: Hotel Booking Process Flow

Fig 6: Hotel Booking Process Flow

How It Works:

-

Step 1: Email Processing – The AI scans and categorizes incoming booking emails from travel agents.

-

Step 2: Booking Data Extraction – Essential details such as guest names, check-in/check-out dates, and room preferences are accurately extracted.

-

Step 3: System Entry – The bot enters booking details into the hotel's reservation system, minimizing manual effort.

-

Step 4: Confirmation Email Generation – A confirmation email with the booking reference is automatically generated and sent.

-

Step 5: PDF Storage – Confirmation emails are converted into PDFs and securely stored for future reference.

-

Step 6: Report Logging – Guest information, agent details, and booking timestamps are logged in a structured format for seamless tracking.

By automating hotel reservations, hospitality businesses can improve operational efficiency, reduce manual errors, and offer a seamless guest experience.

AI-Driven Guest Experience Personalization

Agentic AI offers hyper-personalized services that extend beyond initial recommendations to real-time, adaptive services that adjust based on guest behavior throughout their stay.

-

Behavioral Analysis: AI systems track and analyze guest behavior during their stay, including interactions with hotel facilities, service usage, and past preferences to anticipate needs in real time.

-

Adaptive Services: AI can adjust room settings such as temperature, lighting, or entertainment preferences based on the guest's historical preferences or immediate actions. If a guest frequently orders a specific type of room service, the system can proactively offer those services.

-

Customized Experiences: The AI can suggest personalized activities, events, or local experiences based on the guest's interests, creating a more engaging and unique experience.

Smart room management allows guests to control room settings via voice commands or apps, creating a seamless experience. Real-time personalization increases guest satisfaction and drives revenue opportunities, such as up-selling services.

Streamlined Operational Efficiency

Agentic AI systems streamline operational workflows by automating routine processes, allowing staff to concentrate on high-value guest interactions.

-

Resource Allocation: Intelligent systems predict peak times and allocate resources such as housekeeping, maintenance, and staffing accordingly.

-

Predictive Maintenance: AI monitors equipment and facility conditions, anticipating maintenance needs before they become problematic, reducing downtime and repair costs.

These streamlined operations not only reduce costs but also ensure that guests receive timely, efficient service, creating a more pleasant stay and reinforcing the establishment's reputation for quality and reliability.

Streamlining Sales Order Processing with AI

Agentic AI accelerates sales order creation by extracting purchase order details, validating data, and updating ERP systems, enabling faster processing and improved order accuracy.

How It Works:

-

Step 1: Purchase Order Retrieval – The AI system captures and organizes incoming orders from emails and other sources.

-

Step 2: Data Extraction – OCR technology extracts purchase order details such as product names, quantities, and pricing.

-

Step 3: System Update – The extracted information is entered into the ERP system or SAP with high accuracy.

-

Step 4: Validation Checks – AI runs stock availability and pricing validation checks to ensure order feasibility.

-

Step 5: Order Approval & Processing – The validated orders are routed for necessary approvals before final processing.

-

Step 6: Invoice Generation – Once approved, the system generates invoices automatically, ensuring seamless financial processing.

By automating sales order processing, businesses reduce turnaround time, minimize data entry errors, and enhance customer satisfaction with faster order fulfillment.

Automating Guest Review Analysis

In today's digital age, customer reviews are vital in shaping a hotel's reputation. APA automates the analysis of guest reviews from platforms like TripAdvisor, Google Reviews, and Booking.com by:

-

Extracting guest feedback from multiple platforms

-

Categorizing reviews based on sentiment analysis (positive, neutral, negative)

-

Identifying areas of improvement, such as cleanliness, service quality, and food preferences

Hotels can use these AI-generated insights to enhance guest experiences and improve service quality.

Agentic AI and Agentic Process Automation Benefits in Travel and Hospitality Industry

Agentic AI and Agentic Process Automation (APA) enhance operational efficiency, reduce costs, and improve guest experiences in the hospitality and tourism sector. The key benefits include:

-

Improved Efficiency and Speed: Agentic AI and APA accelerate booking management, check-ins, and billing, reducing manual workload and service delays, while making decision-making faster and more precise.

-

Cost Savings and Reduced Labor Expenses: By automating complex tasks, businesses can reduce staffing costs without sacrificing service quality, optimizing resources efficiently.

-

Enhanced Customer Experience: AI chatbots and automated systems provide instant responses, personalized recommendations, and seamless guest interactions, offering a customized experience for each guest.

-

Minimized Errors and Improved Accuracy: APA and Agentic AI reduce human errors in data entry, payment processing, and availability checks, ensuring smooth, error-free operations.

-

Better Data Management and Insights: These intelligent systems analyze customer data in real-time, helping businesses optimize pricing, marketing strategies, and service offerings for improved guest satisfaction and increased profitability.

Protecting Privacy: Best Practices for Agentic AI in the Hospitality Industry

As the hospitality industry adopts Agentic AI and Agentic Process Automation, safeguarding guest data and ensuring privacy must remain a top priority:

Future of Travel and Hospitality Industry with Agentic AI

The future of travel and hospitality is intertwined with the advancement of Agentic AI and APA technologies:

Increased Adoption

More organizations are realizing the transformative impact of agentic automation on cost, efficiency, and guest satisfaction, accelerating industry-wide adoption.

Integration with IoT

Combining APA systems with IoT will lead to hyper-personalized services — such as smart room environments, real-time check-in automation, and AI-driven concierge support.

Enhanced Data Security

As agentic systems scale, cybersecurity innovations will ensure stronger protection of guest information while enabling deeper insights and personalization.

Innovative Guest Experiences

APA will pave the way for immersive experiences like VR-based hotel previews and predictive travel planning that adapts in real time based on guest preferences and behaviors.

As the global traveler population grows, the demand for intelligent travel assistants is rising. Guests depend on AI agents to recommend destinations, locate hotels, and understand travel protocols. Agentic process automation allows these tasks to be executed at scale — from booking confirmations to real-time support. Guests receive automated updates via preferred channels, while those lacking digital access can still receive support via human agents enabled by AI-driven insights.

The hospitality sector is rapidly embracing APA to scale operations, boost ROI, reduce labor costs, and align with digital expectations. These systems not only optimize core functions like reservations and billing but also help deliver personalized, consistent, and seamless guest journeys.

Key Actions for Adopting Agentic AI in Hospitality

For companies looking to stay competitive in the age of Agentic AI, the path forward is clear:

-

Invest in Technology: Upgrading legacy systems and integrating agentic automation technologies should be a top priority to stay ahead of evolving guest expectations.

-

Focus on Data Integration: Establish robust frameworks for collecting, unifying, and analyzing data to fully unlock the insight-driven potential of agentic processes.

-

Prioritize Security: With APA systems handling sensitive customer information, implementing strong cybersecurity measures is essential for compliance and trust.

-

Training and Adoption: Staff need to be trained to collaborate with intelligent agents and leverage these technologies to embrace automation of repetitive tasks, enhance human decision-making, and guest engagement.

-

Pilot and Scale: Start with pilot programs to test the effectiveness of Agentic AI. Once proven, scale these systems to transform operations organization-wide.

By taking these steps, travel and hospitality providers can harness Agentic AI to build more efficient, intelligent, and guest-focused businesses.

Driving Innovation Across Travel and Hospitality with Agentic AI

The integration of Agentic AI into the hospitality industry isn’t just a trend—it’s a strategic transformation shaping the future of service and operations. From automating complex decisions to delivering personalized experiences, APA is redefining how hospitality brands respond to modern guest needs and business challenges.

Agentic AI is rapidly revolutionizing the travel and hospitality landscape—from real-time personalization and predictive planning to dynamic pricing and intelligent automation. By understanding its potential and embracing innovative use cases, companies can overcome industry hurdles and lead the next era of intelligent hospitality.

Embracing APA technologies enables hotels and resorts to operate smarter, reduce friction in guest experiences, and deliver on the promise of digital excellence. As Agentic AI evolves, so will the opportunities to innovate—those who act early will shape the future of travel and hospitality.

Next Steps in Implementing Agentic AI

Talk to our experts about implementing Agentic AI systems. Learn how the travel and hospitality industry is adopting agentic workflows and decision intelligence to become more guest-centric. Leverage AI to automate and optimize guest services, operations, and support—enhancing efficiency, personalization, and responsiveness.

.webp?width=1921&height=622&name=usecase-banner%20(1).webp)