Digital Twin Technology is a transformative concept that combines physical systems with digital models to create a dynamic, real-time representation of the real world. These virtual replicas are continuously updated with data from sensors, devices, and systems, enabling organisations to understand, analyse, and optimise the performance and behaviour of physical assets without direct intervention.

Originally used in manufacturing and aerospace, digital twins have rapidly expanded into sectors like healthcare, energy, automotive, construction, and smart cities. By mirroring the physical environment, digital twins empower teams to simulate scenarios, predict outcomes, detect anomalies, and make data-driven decisions with greater precision and speed.

The core strength of digital twin technology lies in its ability to integrate IoT, AI, machine learning, and data analytics into one cohesive framework. This integration provides real-time insights and supports long-term strategic planning and innovation. Whether optimizing a factory floor, improving patient outcomes, managing energy grids, or designing safer vehicles, digital twins offer a scalable and intelligent approach to managing complexity and driving efficiency.

Why Digital Twins Are More Relevant Today

The adoption of Digital Twin technology has accelerated in recent years due to a combination of global disruptions, technological advancements, and industry-specific challenges. Businesses and governments increasingly leverage Digital Twins to improve decision-making, enhance operational efficiency, and build resilience against uncertainties. Below are the key factors driving this surge in relevance:

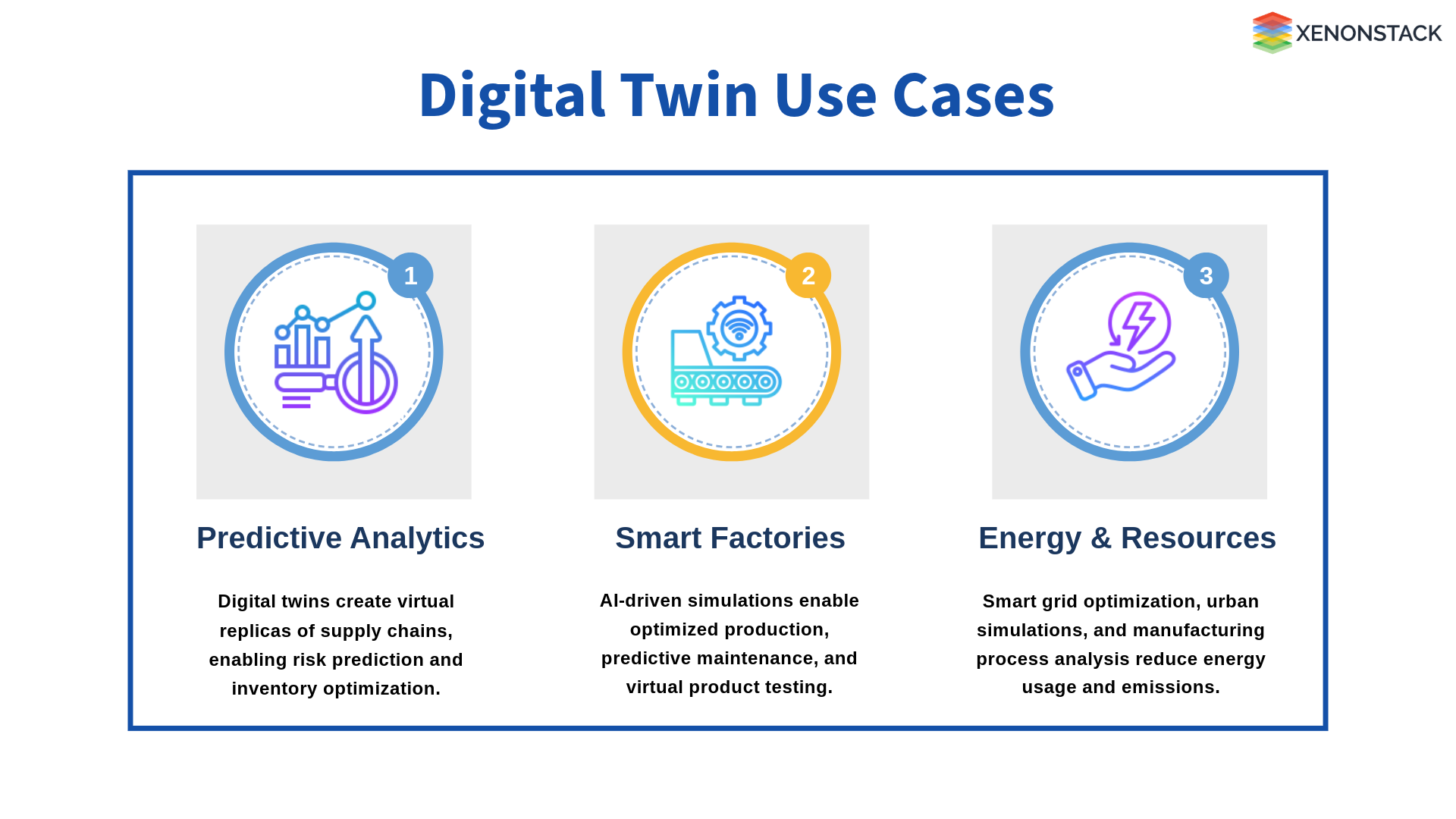

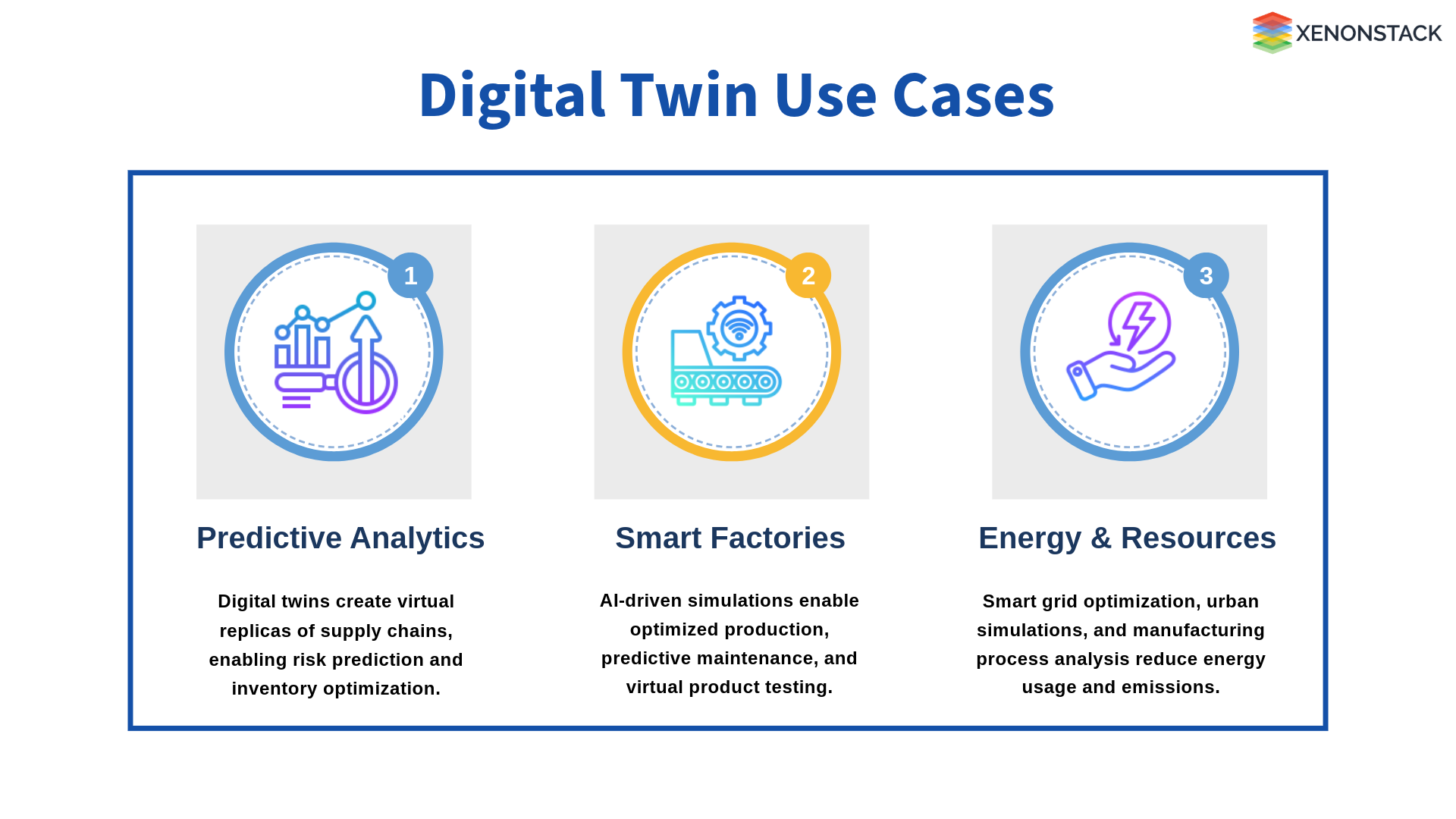

Fig - Use Cases of Digital Twin

Need for Predictive Analytics

The COVID-19 pandemic, geopolitical conflicts, and economic fluctuations have severely impacted global supply chains. Businesses face:

-

Supply chain bottlenecks: Delays in raw materials, production, and logistics.

-

Unpredictable demand fluctuations: Consumer behaviour shifts rapidly.

-

High transportation costs & inefficiencies: Rising fuel prices and trade restrictions.

-

Lack of end-to-end visibility: Companies struggle to monitor supply chain risks in real-time.

How Digital Twins Solve This Issue:

End-to-End Supply Chain Visibility

Predictive Analytics for Risk Management

Inventory Optimization

Real-Time Logistics Monitoring

Smart Factories & AI-Driven Workflows

With the rise of Industry 4.0, companies face pressure to:

-

Increase automation and reduce manual intervention.

-

Improve manufacturing efficiency and reduce costs.

-

Optimize machine performance to prevent unexpected failures.

-

Create smart factories that adapt to changing production demands dynamically.

How Digital Twins Solve This Issue:

Smart Manufacturing & AI-Driven Optimization

Virtual Prototyping & Product Design Optimization

AI-Driven Quality Control

Optimizing Energy & Resources

With increasing concerns over climate change, carbon emissions, and energy consumption, companies and governments must:

-

Reduce carbon footprints and optimize energy usage.

-

Enhance sustainable practices in production and logistics.

-

Implement smart energy management in cities and buildings.

-

Monitor and reduce waste in industrial processes.

How Digital Twins Solve This Issue:

Energy Consumption Optimization in Smart Grids

Sustainable Urban Development

-

Smart buildings use Digital Twins to reduce heating, ventilation, and air conditioning (HVAC) costs, cutting energy usage.

Waste & Emission Reduction in Manufacturing

The Digital Twin Ecosystem

A Digital Twin is not just a static model but a dynamic, data-driven system that continuously evolves alongside its real-world counterpart. To function effectively, a Digital Twin consists of multiple interdependent components that collect, process, analyze, and visualize data in real-time.

Fig - Digital Twin Ecosystem

Fig - Digital Twin Ecosystem

Physical Asset: The Real-World Object or Process Being Replicated

The foundation of any Digital Twin is the physical entity it represents. This could be:

-

A machine (e.g., an aircraft engine, a wind turbine, a robotic arm).

-

A process (e.g., a production line, a logistics workflow).

-

An environment (e.g., a city, a smart grid, an oil refinery).

The Digital Twin continuously receives real-time updates from its physical counterpart, allowing engineers and decision-makers to monitor and optimize operations remotely.

IoT Sensors & Data Feeds: Capturing Real-Time Data

To replicate a physical entity digitally, real-time data collection is essential. IoT sensors and connected devices gather information on key parameters such as:

-

Temperature, pressure, and humidity (e.g., in manufacturing plants).

-

Speed, vibration, and torque (e.g., in industrial machinery).

-

GPS and location tracking (e.g., in logistics and supply chains).

-

Energy consumption and emissions (e.g., in smart buildings and power plants).

These sensors continuously transmit data to the Digital Twin, ensuring that the virtual model remains accurate and up to date.

Data Integration & Analytics: AI/ML Models for Optimization

Once data is collected, it must be processed and analyzed. AI and Machine Learning (ML) algorithms play a crucial role in:

-

Detecting anomalies and predicting failures before they occur.

-

Identifying optimization opportunities (e.g., reducing energy consumption, improving workflow efficiency).

-

Providing actionable insights to human operators or triggering automated response

Data integration platforms consolidate structured (sensor readings, logs) and unstructured (video, audio) data, enabling holistic decision-making.

Visualization & Simulation Tools: AR/VR, 3D Models, and Dashboards

To interact with a Digital Twin effectively, businesses rely on visualization and simulation tools such as:

-

3D CAD Models → Creating virtual representations of physical assets.

-

Augmented Reality (AR) & Virtual Reality (VR) → Enabling immersive real-time interaction.

-

Interactive Dashboards & Control Panels → Providing real-time operational insights.

These tools help engineers, operators, and decision-makers understand complex systems, test scenarios, and make informed decisions without disrupting real-world operations.

Automation & Decision-Making: AI-Driven Recommendations and Action

Digital Twins are not just passive monitoring tools—they enable autonomous decision-making through:

-

AI-driven recommendations → Suggesting actions based on predictive analytics.

-

Automated responses → Adjusting machine parameters in real time.

-

Human-in-the-loop decision-making → Alerting operators for manual interventions when necessary.

By integrating Robotic Process Automation (RPA) and AI, Digital Twins can optimize operations without human intervention, leading to improved efficiency and cost savings.

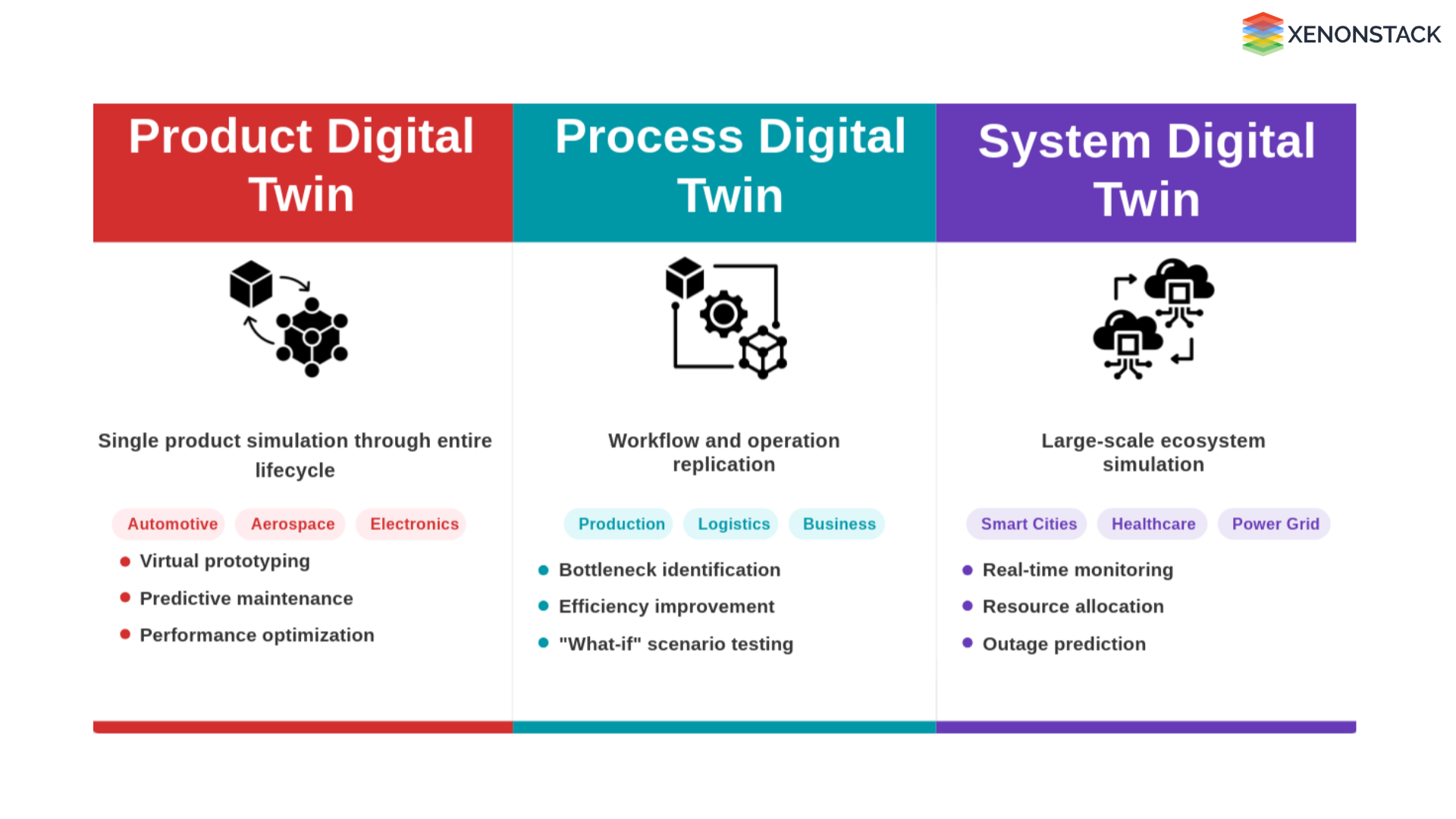

Types of Digital Twins

Digital Twins can be categorized based on the scope and complexity of the system they replicate.

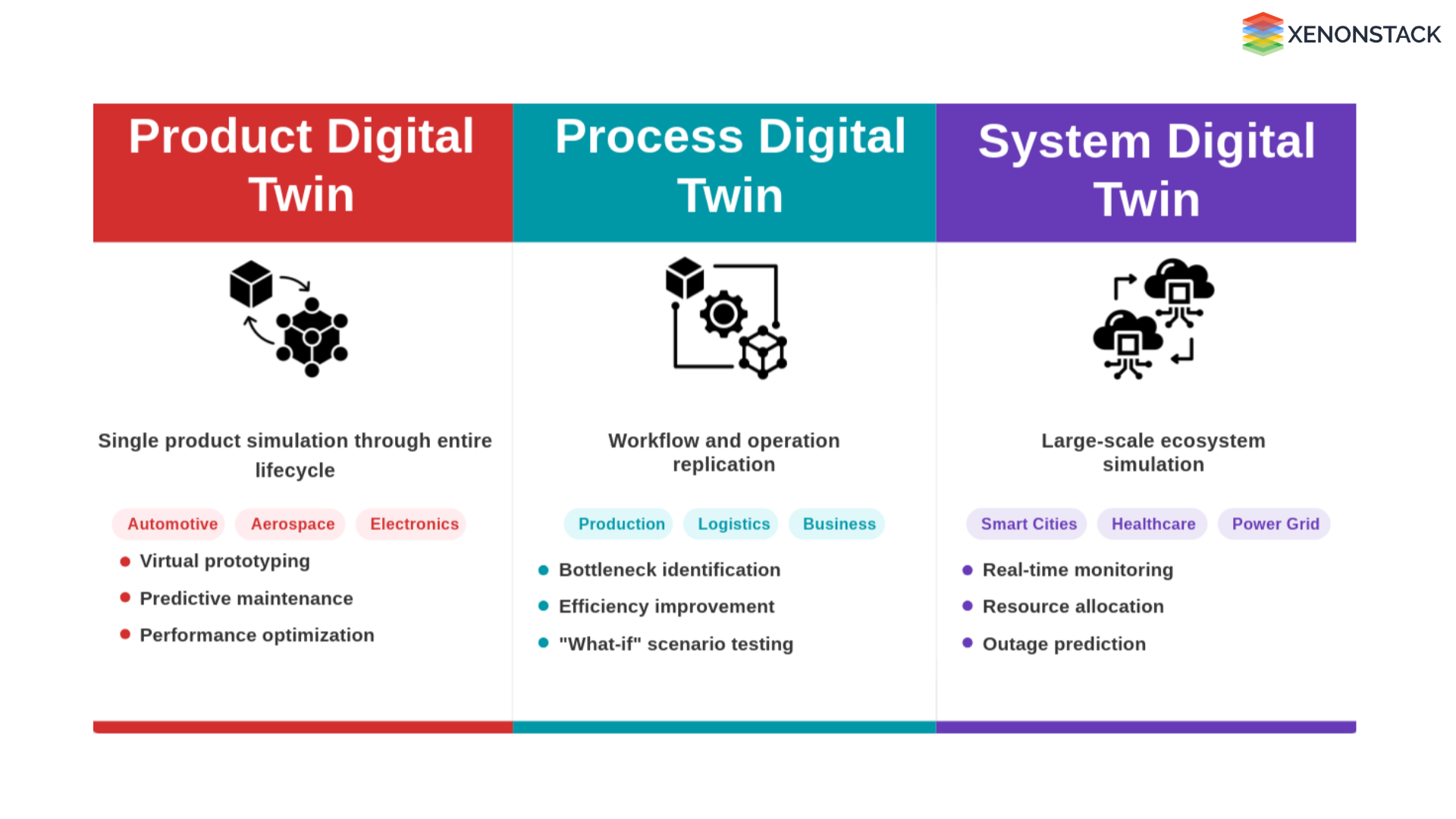

Fig - Digital Twin Types

Product Digital Twin: Tracking Product Design, Testing, and Performance

-

These Digital Twins simulate individual products across their lifecycle, from design to production to usage.

-

Used in automotive, aerospace, and electronics industries to optimize product performance.

-

Helps in virtual prototyping before manufacturing, reducing R&D costs.

-

Monitors real-time product performance for predictive maintenance and over-the-air updates.

Process Digital Twin: Modeling Complex Workflows

Instead of a single product, this Digital Twin replicates an entire workflow or operation, helping industries:

-

Simulate and optimize production lines, logistics, and business processes.

-

Improve efficiency by identifying bottlenecks and streamlining operations.

-

Reduce operational risks by testing “what-if” scenarios before implementation.

System Digital Twin: Replicating Interconnected Environments

These Digital Twins simulate large-scale ecosystems involving multiple interconnected components, such as:

-

Smart Cities → Monitoring traffic, pollution, energy grids, and infrastructure in real time.

-

Healthcare Systems → Simulating hospital operations, patient care, and resource allocation

-

Power Grids → Optimizing energy distribution and predicting outages.

The Role of IoT, AI, and Cloud in Digital Twins

IoT Sensors: Capturing Real-Time Performance Data

-

IoT devices continuously collect, transmit, and process real-world data for the Digital Twin.

-

Enables real-time monitoring of equipment, vehicles, and supply chains.

-

Ensures seamless connectivity between the physical and digital worlds.

IoT is the backbone of Digital Twins, enabling real-time data flow between physical assets and their digital replicas.

AI & ML: Predicting Failures and Optimizing Processes

-

AI-driven analytics identify patterns, detect anomalies, and optimize system performance.

-

Machine Learning (ML) models improve over time, enabling better predictions and decision-making.

-

AI helps in self-healing systems, where the Digital Twin can autonomously fix problems.

Cloud & Edge Computing: Ensuring Scalability and Real-Time Processing

-

Cloud computing provides scalable storage and computational power to process vast amounts of IoT data.

-

Edge computing enables real-time decision-making by processing data closer to the source (e.g., within a factory or on a wind turbine).

-

Hybrid models leverage both cloud and edge computing for low-latency, high-efficiency operations.

Core Technology Stack of Digital Twins

.png?width=1920&height=1080&name=Xenon%20Daily%20Work-80%20(1).png)

Fig - Technology Stack of Digital Twins

IoT Sensors & Data Feeds

Types of Sensors:

Data Sources:

-

Sensors generate structured data (e.g., temperature, pressure) and unstructured data (e.g., images, audio).

Data Integration & Analytics

Real-time Data Processing: Using Apache Kafka, Apache Flink, and Spark Streaming.

AI & ML Models:

Visualization & Simulation Tools

Augmented Reality (AR) & Virtual Reality (VR): Helps operators interact with the digital twin in an immersive environment.

3D Modeling & Simulation:

-

Siemens NX, Ansys, and Dassault Systèmes: Physics-based simulations for engineering applications.

-

Interactive Dashboards: Power BI, Grafana, and Tableau for real-time monitoring.

Automation & Decision-making

AI-Driven Recommendations: Digital twins analyze real-time data and suggest adjustments.

Closed-Loop Automation:

-

AI models trigger automatic responses in industrial systems (e.g., adjusting robotic arm speed in manufacturing).

-

Digital twins integrate with ERP and MES (Manufacturing Execution Systems) for process automation.

While Digital Twins offer transformative benefits across industries, they also come with significant challenges. These challenges range from technical complexities to financial constraints, security risks, and ethical concerns. Below is an in-depth analysis of these limitations and their possible solutions.

.webp?width=1921&height=622&name=usecase-banner%20(1).webp)

.png?width=1920&height=1080&name=Xenon%20Daily%20Work-80%20(1).png)